The core of our company lies

in the minds of our team

and their expertise.

Development

The cornerstone of our company and our greatest strengths is a combination of our exceptional team with their extensive know-how, experience, and their commitment to be the best. Our greatest source of pride stems from the synergy of our extraordinary team and the depth of their knowledge, driving innovation and excellence in all that we do.

At HStec Glass Systems we are continually in communication with all the leading mould makers and glass container producers to develop their needs and requirements, and so we promise you that we will be your “one-stop“ preferred supplier to introduce you to new upcoming products and developments.

First AI Pilot Project in the Glass Container Industry

At the beginning of this year, we introduced an exciting innovation using AI technology, marking the first pilot project in the Glass Container Industry. This groundbreaking initiative aimed to revolutionize the way we approach quality control and manufacturing processes within the glass industry. Alongside this, we focused on new product developments to enhance both Hot End production and Cold End mould maintenance, further advancing our mission to improve operational efficiency and product quality.

Our commitment to improving quality did not stop with these new developments. We continued to upgrade our existing product range with the latest advancements in parts and technology, ensuring that we remain at the cutting edge of the glass industry. These ongoing enhancements are crucial in helping us maintain our position as a leader in the field, committed to delivering superior products and solutions to our clients.

As a result of these innovations and our drive for excellence, we successfully developed the OSCAR Scanning System, a product designed to push the boundaries of glass container manufacturing. The OSCAR Scanning System represents a significant leap in automating the inspection process, offering a level of precision and efficiency that was previously unattainable with traditional manual methods. This advancement is part of our ongoing effort to reduce human error, enhance production consistency, and ensure defect-free output across all stages of manufacturing.

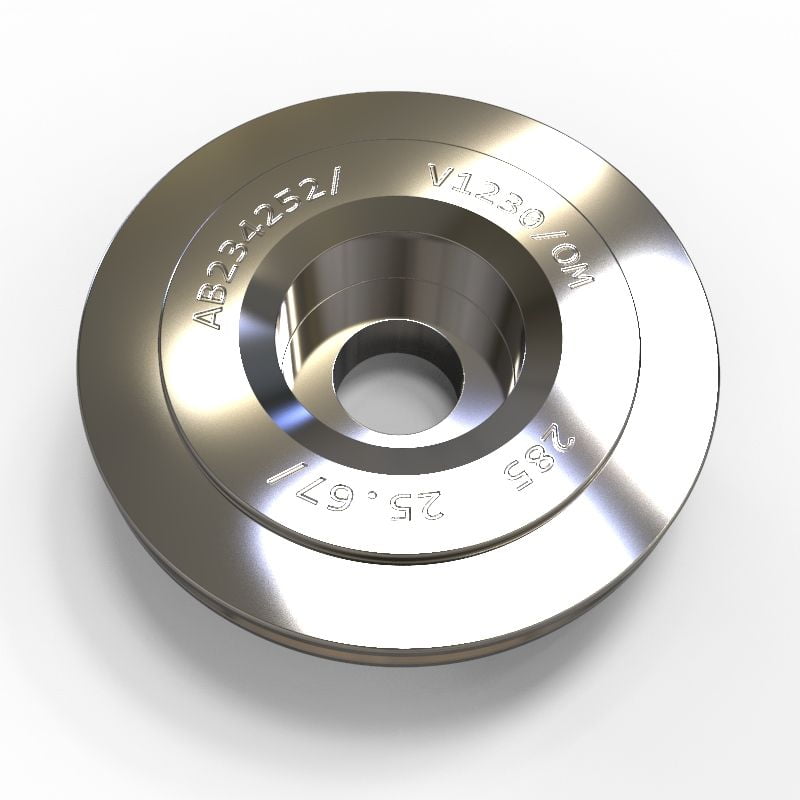

In addition to OSCAR, we are proud to introduce another groundbreaking product: the AIQ Workstation. The AIQ Workstation transforms guide plate quality inspection in glass container manufacturing by automating the process using AI technology. Traditional manual checks are prone to human error, but the AIQ Workstation provides 100% accurate inspections with high-resolution cameras and AI-driven anomaly detection. It identifies defects such as scratches, dents, and micro-inconsistencies, ensuring consistently high-quality glass container mould equipment.

With its modular design, the AIQ Workstation can be used as a standalone unit or integrated into automated systems. It also features Optical Character Recognition (OCR) for traceability, linking each inspection to specific workpieces, and real-time data access for quicker responses to anomalies. By automating inspections, the AIQ Workstation improves product quality, reduces defects, and enhances operational efficiency, making it an invaluable tool for the future of glass container manufacturing.

Advancements in Mould Displacement

Our range of mould displacement bladders are proving to be significantly improved in life and durability. Our relentless pursuit of excellence propels us closer to eliminating manual displacement entirely. Despite already supplying the fastest and most accurate mould displacement machine in the industry, we remain committed to pushing the boundaries even further.

Partnership for Air Quality Solutions

The success of our commitment to contemporary demands is our latest partnership with the world-leading company in air quality solutions- Plymovent. The project is providing a working space with improved employee working conditions to meet the upcoming 2025 EU Nickel Regulations, our complete solution is already being adopted in multiple mold shops throughout the world.

2024 will prove to be an exciting year and we invite you to become one of our continually growing list of friends and partners in the Glass Container World.