AI-Powered OCR Solution for Engraved Metal Text

We are sure you have met the old traditional OCR systems that fail when it comes to decoding engraved text on metal surfaces, and that slows down your business and raises your costs.

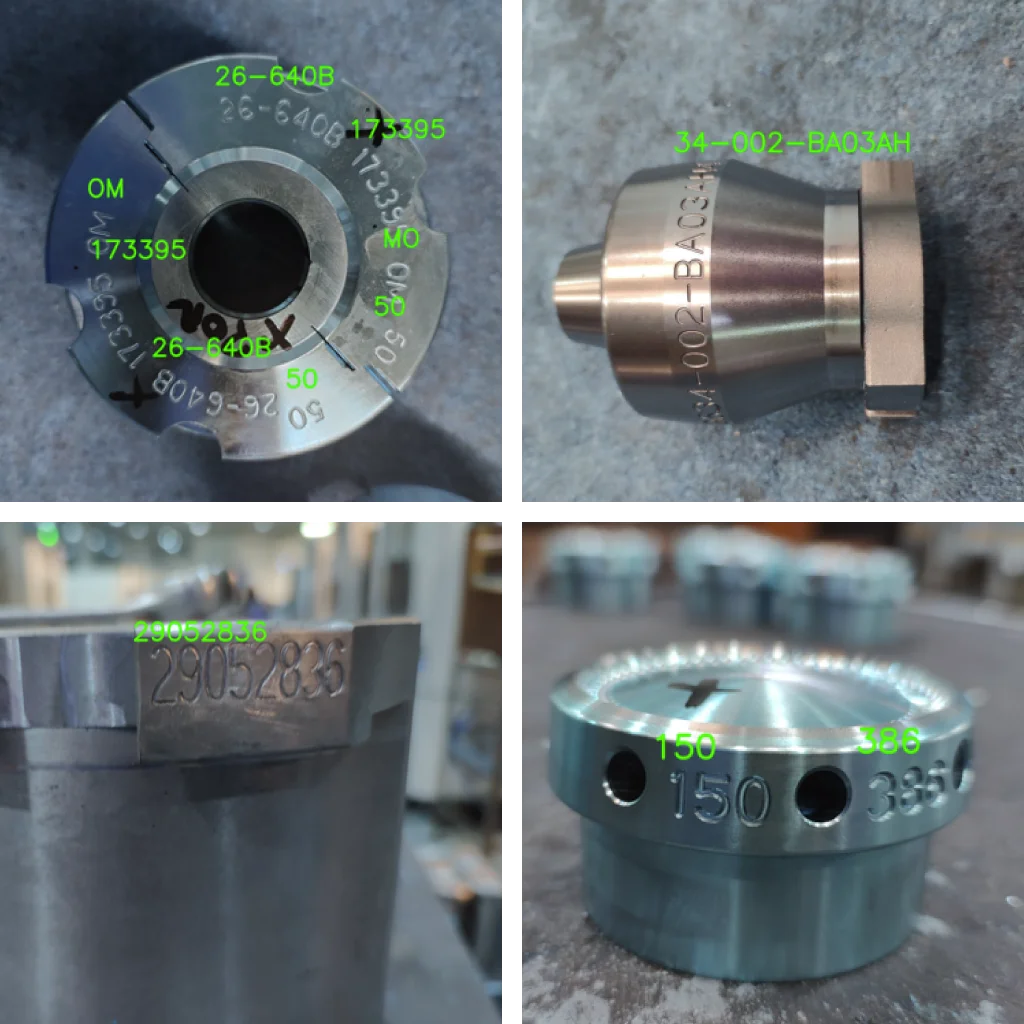

HSTec Glass Systems AI-based OCR scanning is specifically designed for the identification of engravings on moulds, blanks, and all other production toolings.

It recognizes robust and accurate character through advanced AI learning.

With a self-improvement management system, it continuously learns and adapts, ensuring optimal performance. The user-friendly interface facilitates seamless on-premises integration, enabling fast and instant communication. Moreover, our device offers complete cyber protection from external threats, ensuring the security of your internal data. The entire process is achieved in approximately 3 seconds, making it a highly efficient solution for your business.

This is the first pilot project in the Glass Container Industry that showcases its potential for only even higher accuracy through continuous learning capabilities.

Our specialized OCR solution is precisely engineered to excel in decoding engraved characters on even the most challenging metal substrates. It provides unmatched accuracy every time, and therefore seamless efficiency in your business.

Powered by the most modern and advanced machine learning algorithms, our OCR technology has been trained on diverse datasets to recognize and transcribe engraved text with exceptional precision of over 99%. It adapts to various lighting conditions and surface textures, ensuring reliable performance in any environment.

Industrial Applications: You can seamlessly integrate our OCR solution into your manufacturing processes for automated inspection and quality control. In today’s industry, there is no space for costly errors and delays—our system helps you to ensure the integrity of engraved information, enhancing product reliability and traceability.

It is versatile and efficient, whether you’re decoding alphanumeric codes, serial numbers, or product specifications, our AI-powered OCR technology streamlines workflows and boosts productivity across industries.

Experience the future of OCR technology today with our game-changing solution for engraved metal text. Elevate your operations, eliminate inefficiencies, and stay ahead of the competition—discover the power of precision with us!

This is the first pilot project in the Glass Container Industry that showcases its potential for only even higher accuracy through continuous learning capabilities.

The AIQ Workstation:

A Future-Ready Solution for Glass Container Manufacturing

The AIQ Workstation is a cutting-edge solution for quality control in glass container mould equipment manufacturing. With its modular design, scalable hardware, and advanced connectivity, the AIQ Workstation is an invaluable tool for maintaining consistent product quality in an industry where precision and reliability are crucial. Embrace the future of manufacturing with the AIQ Workstation and experience unmatched quality control and operational efficiency.

The Future of Automated Quality Control

HSTec Glass Systems’ AIQ Workstation redefines quality control by offering a fully automated, AI-powered inspection system. Designed to replace manual checks, the AIQ Workstation delivers 100% accuracy in detecting defects, ensuring that every guide plate meets the highest quality standards. This advanced solution eliminates human error and offers a reliable, efficient inspection process, resulting in superior product quality and reduced production costs.

The AIQ Workstation is a versatile solution that can be deployed as a standalone unit or integrated into an automated robotic cell. Its compact design allows it to fit easily into various production settings, even those with limited space. Whether used individually or as part of an automated production line, the AIQ Workstation adapts to the specific needs of glass container manufacturing, ensuring optimal efficiency and flexibility.

AI-Driven Anomaly Detection for Flawless Quality

Equipped with high-resolution cameras and sophisticated AI-driven anomaly detection algorithms, the AIQ Workstation identifies a wide range of defects on glass container mould parts, such as scratches, dents, and micro-inconsistencies. These issues, though small, can significantly impact the quality of the final product. The system’s ability to detect even the most minor defects ensures that every guide plate meets stringent quality standards. Additionally, the AIQ Workstation can be upgraded with additional cameras to expand its coverage, further improving its precision and ability to capture subtle deviations.

One of the standout features of the AIQ Workstation is its Optical Character Recognition (OCR) capabilities. This technology reads engravings on each guide plate, providing full traceability of every inspection. The system links each inspection result to a specific workpiece, creating a comprehensive record of quality compliance. This traceability not only helps in identifying defect patterns but also enables quality control teams to make data-driven improvements to the production process.

With advanced connectivity options, the AIQ Workstation allows quality control teams to access real-time inspection data. Integrated into the local network, it provides instant insights, enabling quicker responses to production anomalies. For remote monitoring, the system offers 5G connectivity, allowing off-site diagnostics and oversight. This flexibility ensures that critical inspection data is accessible from anywhere, supporting a proactive and dynamic approach to quality management.

By automating the inspection process, the AIQ Workstation significantly reduces the inconsistencies and physical strain associated with manual checks. It guarantees that each glass container mould part meets high-quality standards, minimizing the risk of defects in the final products. The AIQ Workstation’s ability to conduct 100% inspections with precise accuracy enhances the reliability of glass container mould equipment, reduces costly rework, and improves overall production efficiency. This leads to higher product quality, increased customer satisfaction, and optimized operations.

The AIQ Workstation is a cutting-edge solution for quality control in glass container mould equipment manufacturing. With its modular design, scalable hardware, and advanced connectivity, the AIQ Workstation is an invaluable tool for maintaining consistent product quality in an industry where precision and reliability are crucial. Embrace the future of manufacturing with the AIQ Workstation and experience unmatched quality control and operational efficiency.

AIQ Workstation: Revolutionizing Quality Control in Glass Container Manufacturing

Transforming Guide Plate Inspections with AI-Powered Automation

In the glass container manufacturing industry, quality inspection of components like guide plates is traditionally a manual process, heavily reliant on human operators. Guide plates, which form the top portion of glass containers, must be meticulously inspected for defects to ensure they function correctly. However, this inspection process is prone to human error, fatigue, and inconsistencies, especially during extended shifts. Manual checks often lead to missed defects, impacting the overall quality of the glass containers produced.